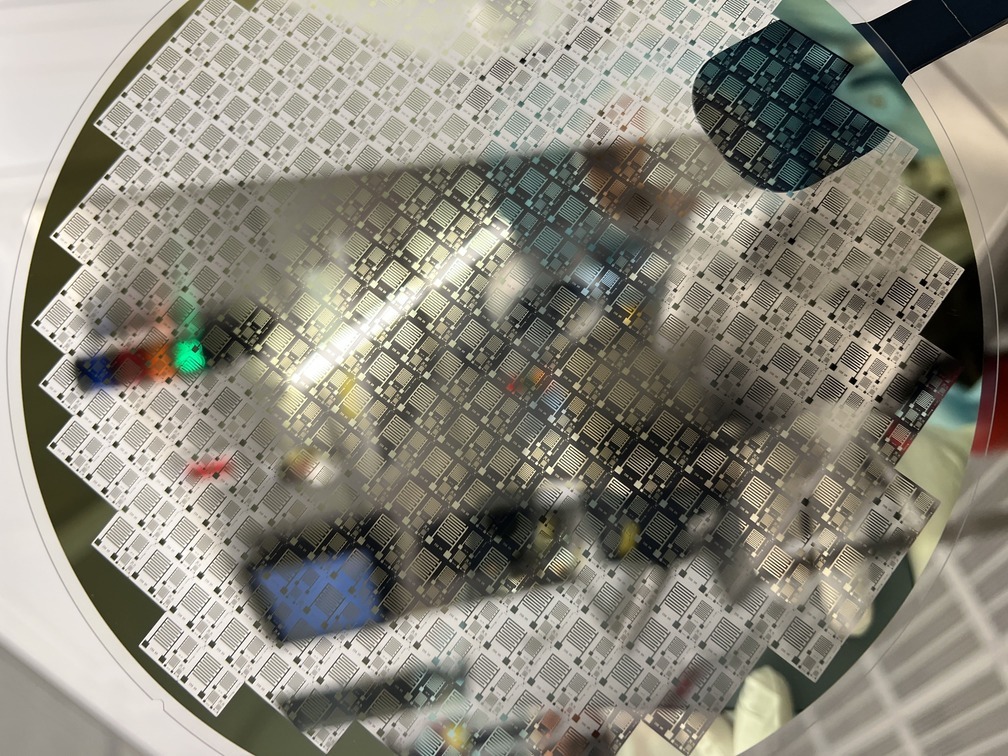

© Fraunhofer IMS

The transformation to a digitalised and increasingly autonomous world requires a large number of sensor systems in infrastructures and infrastructure. At the High-Performance Center for Terahertz Sensor Technology, we cover the entire value chain of terahertz technology – from semiconductor design and sensor concepts to real-time implementation:

© Fraunhofer IMS

© Fraunhofer IMS

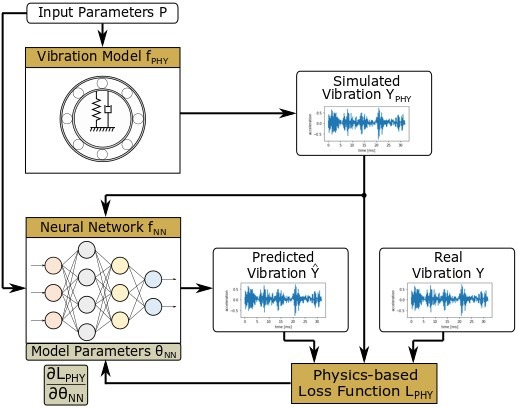

Innovative AI solutions for real-time analyses.

Using energy-efficient AI accelerators in modern technology nodes (in-memory computing, e.g. 22 nm FDSOI or 28 nm HKMG), we optimise real-time analyses for radar data classification or imaging sensor technology in production processes.

In this way, we support non-destructive and non-contact classification of material properties or 3D environment recognition.

Our high-performance concepts for heterogeneous back-end structures based on microcontrollers, FPGAs, GPUs and CPUs for sensor control and sensor fusion. We use distributed signal processing systems on dedicated hardware for this purpose.

The fields of application for our solutions are diverse: biomedical sensor technology, joint communication and sensing (JCS), sorting in the circular economy, monitoring process-relevant parameters in the raw materials or food processing industry, as well as sensor technology for autonomous driving and flying.

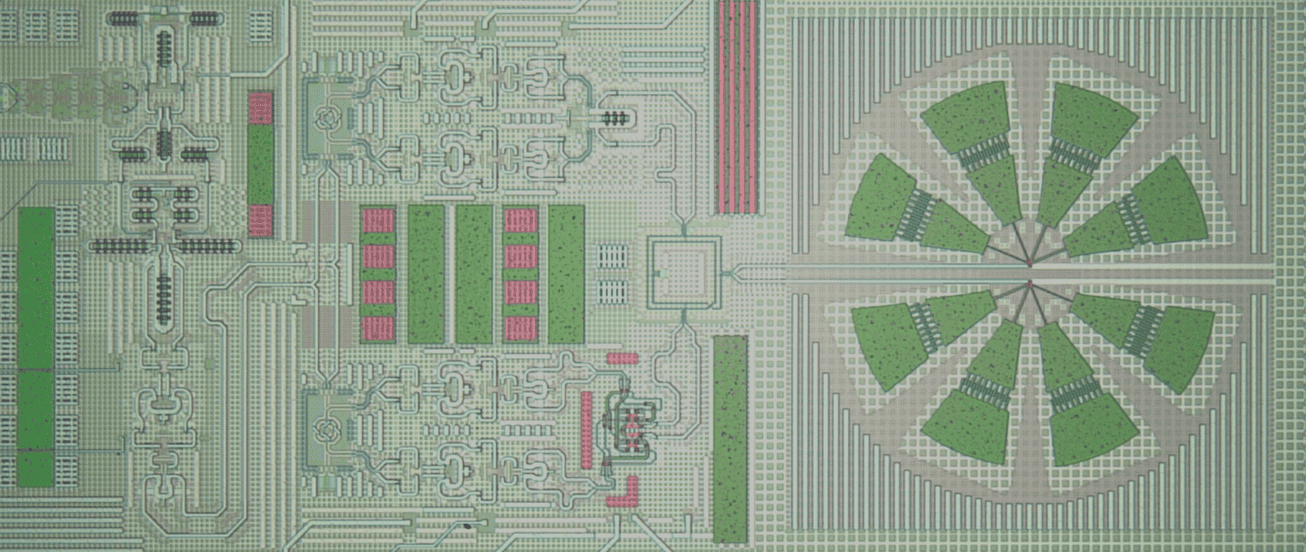

Terahertz technologies for scalable industrial applications

Our customised high-frequency front ends operate in the frequency range from 60 to 500 GHz. We have also been able to provide proof of functionality for electronically generated terahertz systems up to 2.5 THz.

Here we draw on our expertise in chip development and the transfer of MMIC technologies for industrial-grade solutions, including transceiver systems in SiGe-BiCMOS technology (e.g. for 240 GHz and 480 GHz). These system solutions enable communication with the highest bit rates (>100 Gbit/s) and precise sensor technology, for example for industrial wireless links or quality assurance.

Cost-effectiveness, industrial suitability and scalability are the guiding criteria for us when developing our solutions. This is why we not only rely exclusively on terahertz-based solutions, but also combine photonic and electronic concepts with optical components to create hybrid systems if required.

In addition to software and hardware development, our range of services for you naturally also includes consulting and qualification relating to the potential and possible applications of terahertz technology. Talk to us!

© Fraunhofer IMS

Despite strict standards, contamination with foreign bodies occurs time and time again in the production of food. If the foreign body is enclosed in the material mass or packaging, only sensors that are able to X-ray the product can help. But even for these solutions, certain foreign body materials are a challenge.

Our Terahertz sensors reliably detect differences in material and can therefore detect foreign bodies in already packaged goods or recognise incorrect packaging. They do not require ionising radiation and are therefore a comparatively cost-effective option for these problems.

With our sensor solutions, faulty products can be sorted out before delivery, for example, and do not enter circulation in the first place. This avoids the costs of a recall and prevents potential damage to the company’s image.

In steel production rolling mills, the environmental conditions are harsh and extremely challenging for existing sensor solutions for inline quality control: high temperatures of the red-hot steel, strong vibrations, scale and water vapour lead to sensor failures or make their use impossible from the outset.

Together with our partners in the field of commercial sensor solutions, we have developed and increased the robustness radar sensors and brought them into use.

Our sensor system operates 24/7 and the constantly reliable measured values provide feedback to the roll control system in the roll stand. This enables CO2 to be saved through reduced overwidth production and therefore less waste, which has to be melted down again in an energy-intensive process.

Um Ihnen ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn Sie diesen Technologien zustimmen, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn Sie Ihre Zustimmung nicht erteilen oder zurückziehen, können bestimmte Merkmale und Funktionen beeinträchtigt werden.

Adding {{itemName}} to cart

Added {{itemName}} to cart